THE PROCESS - WHAT COFFEE PRODUCTION LOOKS LIKE IN RIGELLO

We are a coffee roastery,

which operates locally,

but it has considerable production capacity. Get to know us closer.

how does the coffee roasting process work?

bean

roasting

cooling

aging

package

control

repeatability

logistics

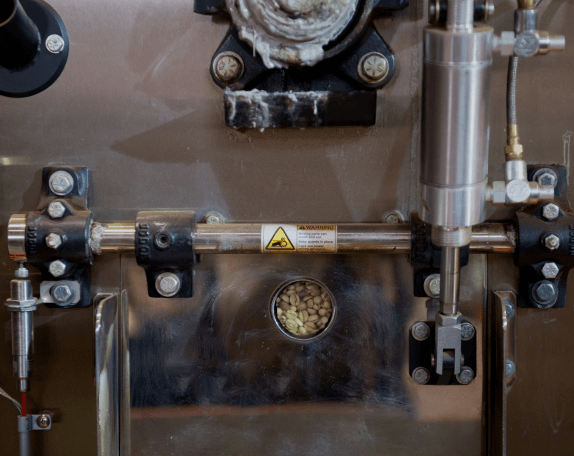

In a coffee roastery, everything starts with the beans. We import ours straight from distant conventional and ecological plantations. We make sure that they come from the latest crops and that they have adequate humidity. On site in Lodz, we subject them to taste and physical-chemical tests. In this way we verify quality, without which there is no good coffee.

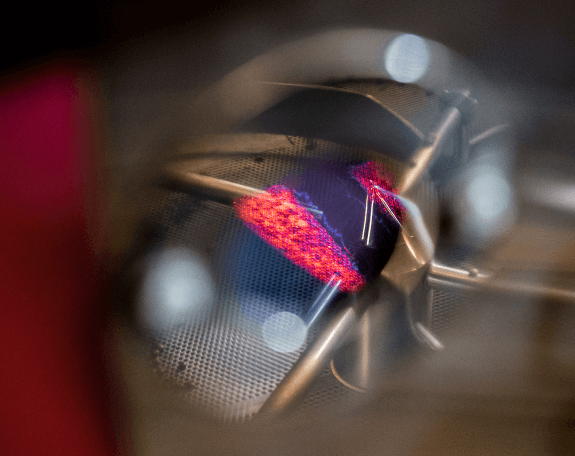

We roast the beans that have passed the selection at a temperature of about 200 degrees Celsius. This is far less than in industrial ovens, where temperatures reach 400 or even 600 degrees Celsius. In addition, our Diedrich oven is equipped with a drum and has a slow roast function. As a result, the process takes from 12 to as much as 22 minutes to extract the full flavor from the beans.

When you take the coffee out of the oven, the temperature is very high, so you need to cool it down. This should be done quickly so that it does not lose its noble taste and aroma. Most roasters pour water over the beans for this purpose. Not with us! At Rigello, hot beans undergo an air cooling process. This firstly allows the coffee to cool down quickly, and secondly ensures that the beans do not soak up water.

Freshly roasted coffee does not taste good at all. It is highly saturated with carbon dioxide. That’s why the beans should go straight from the oven to age. So we move them to silos, where they spend 48h, giving up a lot of the gases accumulated during roasting and oxidizing. Also at this stage, we check that there are no stones hidden between the grains, for example, that could damage the mill.

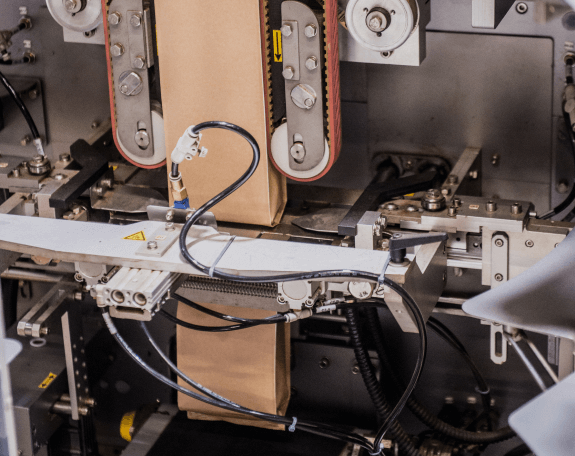

We package the coffee in basic plain packaging or in one with a label or full printing of your choice. Our bags are always three-layered – they have two layers of polyester and one layer of aluminum inside. This guarantees 99.5 percent barrier. A side seal (instead of a back seal) gives stability and better printability, and an activated carbon valve guarantees the aroma of the coffee.

The discarded beans must be weighed and packed. For packaging, we transport them using hermetic pneumatic lines, also used, among others, in the pharmaceutical industry. This protects the beans from damage. We weigh them on return scales to enclose an identical amount of coffee in each package. We also use an X-ray inspector that examines the density of the package’s contents and immediately rejects those containing ingredients other than coffee.

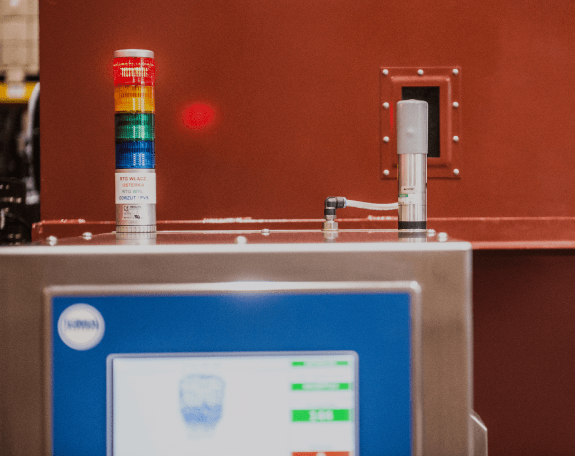

The coffee blends we compose always taste the same. This repeatability of flavor is a result of the choice of beans and the way they are roasted. Its acquisition would not have been possible if not for our furnaces. They are equipped with sensors to record the roasting profiles of each coffee blend we create. In this way, we are able to guarantee customers repeatable taste and aroma of their own brand of coffee.

Finished bags filled with measured coffee are placed in bundles on pallets. Properly secured, they set off on their journey from our warehouse to the location you specify. Pick-up couriers arrive daily to pick up shipments, so you are guaranteed that the coffee you order will arrive as soon as possible. If you don’t want all of it at your place right away, we have a coffee storage service.

Create your own coffee brand with us

Bean. Just as you like, just as

You want – on your terms!